How to Get The Most Out of Your MIG Welder

Looking after your MIG Welding Machine

Just like other things in life, you look after your MIG welding machine and it should look after you in return, but how do we do this?. Although R-Tech Machines are pretty reliable and need little maintenance to keep them ticking over, there are things that can be done to ensure you don't run into problems.

Where to begin with you MIG?

It is important to understand which parts of the machine are classed as a "consumable item" as these are the parts you are going to need to change more frequently. It's no surprise that most of these components are found in the MIG torch. If you start to notice your welds aren't looking as clean as they once did, then there is a good chance that something has decided to give up in the torch head.

So What Parts Make Up the Torch?

Starting with the shroud, this part ensures that your weld is getting the protection it needs from the elements by forcing gas towards the arc. The shroud also protects the other components, we will cover shortly, from spatter being kicked up from the weld. Most of the spatter gathers around the opening of the shroud and causes obstructions for the exiting gas, reducing the coverage. It can also cause the filler wire to arc against the shroud and not on the workpiece. Take a look at the end of the shroud, is it black and covered in spatter?, is it rough on the edges and no longer round?, if so, get it changed!.

MIG Welding Tips

Unfortunately we aren't referring to the handy tricks and tips here, however that information can be found in our MIG Welding Tips & Tricks Blog We are referring to the part on the torch that assists with guiding the wire into the weld pool. Although protected by the shroud, this part can also become victim to welding spatter. As the tip gets hot, the bore slowly melts away and what may have started as a 0.8mm diameter, becomes a 1.0mm diameter and increases the chances of burn back. Have a look at the tip, is it covered in soot? is there wire stuck in the end?, its time to get this swapped over with a fresh tip.

Tip Adaptor

As the name suggests, this part does allow the 6mm threaded tips to be fitted into the torch head however, it does play another vital role in the welding process. The adapter has gas outlet holes located around the body that allows the gas to swirl around the tip, increasing coverage. Although a consumable part, the tip adapter shouldn't need changing to often however, it can get covered in spatter and the threads may become weak due to the intense heat.

What Else Could Go Wrong in the Torch?

Other than what we have already covered, there are two other parts that are usually forgotten about when it comes to torch maintenance.

Torch Liner

The torch liner allows the wire to run smoothly through the torch lead from the machine to the welding tip. Over time, the liner becomes dirty as the wire pushes through it and starts to causes snagging issues within the lead. If you want to know how to change the liner, check out the video below!.

Torch Switch

On the odd occasion our technical team will receive a call regarding the machine not engaging the wire feed, everything is as it should however when the user pulls the trigger, nothing happens. We suggest giving the torch switch a blow out with some compressed air and find that the machine starts working as it should. Dust and dirt can creep its way under the switch and get in the way of the contacts, once this is blown out you should get full use out of the machine once again.

What else can be done to maintain your MIG Welding Machine?

Now that we have covered the torch, what else can be done to ensure that your machine runs smoothly?. As mentioned at the start of this blog, the machines are pretty reliable and need very little in terms of maintenance. It is good practice of course to keep things ship shape and shiny.

Compressed Air

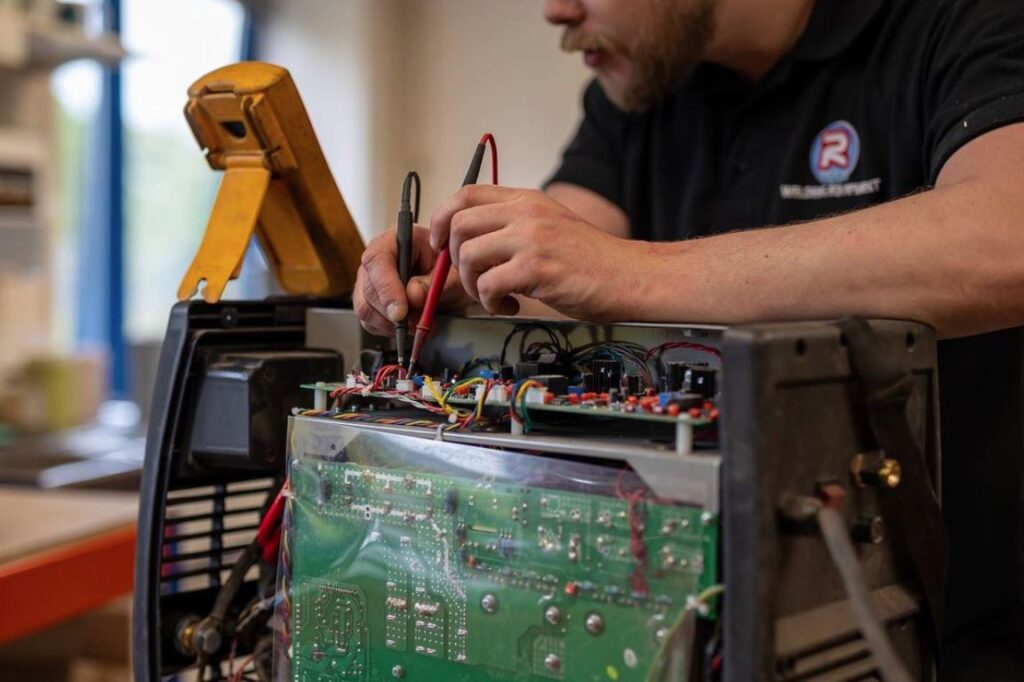

We recommend cleaning your machine with compressed air. It is likely that dust has built up on the components within the machine. Baring in mind that the machine has a fan on the back which is sucking in air constantly, keeping the internals nice and cool. As well as sucking in air, it is pulling everything else with it which will coat the internals and stop them working as efficiently as they should be.

You Will NOT Void Your Warranty

We encourage all customers to maintain their machines the best they can and appreciate this might involve removing the shell protecting the internals. Please do it, if it means you can get into every little nook and cranny to blow off the dust that has gathered in there then feel free. Unlike other companies, we will not void your machines warranty just because you were trying to look after it.

But what happens when things go wrong?

So what happens if something goes pop, bang or whizz inside the machine even though you have maintained it religiously since you took it out the box?. Yes it can happen, at the end of the day its a small unit that punches a lot of power, it is rare for a MIG welder to just give up but we look to get you back up and running as quickly as we possibly can. All machines are backed with an industry leading, no quibble, 3 year warranty.

Technical Support

R-Tech Welding are one of the leaders within the welding supply industry when it comes to supporting the machines manufactured. Our technical support team are always on hand to get things resolved as quickly as they can. If the machine is within warranty the collection, repair and re-delivery should be completely free of charge. If the machine is out of warranty, don't fear as we do not believe in writing off machines and repairs are relatively low cost with a quick turnaround.