R-Tech 261 TFT Digital AC/DC TIG Welder 240v

Intelligent Easy Mode

- Professional weld settings built in - Get great results easily

- Large 5.1" HD Screen

- Simple to use - Easy navigation - no complicated menus - All settings on single screen

- Over 220 built in programs, set up by our R-Tech experts

Professional Mode

- Full control of every weld parameter you could ever need

- Pre-flow Gas, Start Amps, Slope up time, Main amps, Slope down time, End amps and post flow gas

- 5 AC Waveforms - Advanced Square, Soft Square, Triangular, Sine and Trapezoidal wave forms - Giving the ultimate control of weld pool and bead

- AC Frequency to 20-400Hz - Increased arc focus

- AC Amplitude - Advanced AC welding mode - Full independent control of EN- and EN+

- Electronic HF starting for fast arc starting and low interference

- Energy saving - 2x Fan on demand modes - Save power and quiet running

- Water cooler power control - Save on energy and quiet running

- 3 Start modes - HF Fast start, LIFT and LIVE

- Spot and tack weld features with stitch function

- True 4-way trigger latching with control of pre/post flow gas, initial/final amps, slope up/down

- 4TS Trigger mode - Ideal for pipe welding, switch from start to main amps by tapping the torch switch

- VRD Voltage Reduction in MMA - reduces OCV in standby for increased user safety

- 20 professional memory stores

- Amperage Range: DC 2 to 260 Amps - AC 3 to 260 Amps

- 5 year collect and return UK warranty

- Want to try before you buy? Book a demonstration at our Tewkesbury HQ - Available 5 days per week 9am-12pm and 2pm-4pm.

| Amperage range | DC 2-260A, AC 3-260A, MMA 20-210A | ||

|---|---|---|---|

| Duty cycle | TIG 260A 60% - MMA 210A 60% | ||

| Input voltage/amps | 240v 32A - No load voltage 70v | ||

| Memory Stores | 20 | ||

| AC Frequency | 20 - 400 Hz | ||

| AC Balance | 5 - 70 % | ||

| Pulse Frequency | AC Standard 0.1 - 500 Hz | ||

| Mixed AC/DC 01 - 10 Hz | |||

| DC 0.1 - 999.9 Hz | |||

| Pre flow gas | 0 - 60 seconds | ||

| Post flow gas | 0 - 60 seconds | ||

| Slope up | 0 - 30 seconds | ||

| Slope down | 0 - 60 seconds | ||

| Switchable HF Start | Yes | ||

| MMA Arc force | 0 - 100 % | ||

| MMA Hot start | 0 - 2 seconds | ||

| MMA Hot start amps | 0 - 100% | ||

| VRD | Yes - Reduces MMA OCV for user safety | ||

| Gross weight | 35KG | ||

| Dimensions | 438H x 232W x 550L (mm) | ||

| Insulation class | IP21S | ||

| Cooling fan | Fan-On-Demand fan cooling system for quieter operation | ||

| Max Thickness | 9MM Single Pass | ||

| Max Thickness Steel | 22MM Multiple Passes | ||

5 AC Waveforms

- Advanced Square Wave: fast cooling weld pool, deep penetration and fast travel speed

- Soft Square and Sine Wave: Lower arc noise, for a more traditional arc

- Triangular Wave: designed for thin alloys, reduces heat input

- Trapezoidal Wave

Generator Friendly - Recommended minimum of 10KVA 240V and fitted with AVR (auto voltage regulation)

Package contents:

TIG261TFT Digital Tig Welder, 4M WP26 Ultra-Flex Tig Torch, 3M Earth Lead, MMA lead, Argon Regulator, Gas hose, Torch consumables pack.

The R-Tech TIG261TFT carries the following warranty:-

- TIG261TFT - 5 Year Warranty

- FP8 SSC Foot Pedal - 1 Year Warranty

- Regulator - 1 Year Warranty

- R-Tech TIG Torches - 3 Month Warranty

- Earth and Electrode Leads - 3 Month Warranty

- Optional Water Cooler - 5 Year Warranty

R-Tech machines are designed to be robust, easy to use and highly reliable but in the unlikely event that your welder or plasma cutter requires attention, R-Tech promise to:-

- Arrange collection via next working day UK courier [48hr offshore]

- Quickly repair the machine at our Technical and R&D centre in Gloucester

- Deliver back via next working day UK courier [48hr offshore]

- All costs covered by R-Tech - Yes, Collection, repair and delivery!

No questions, no hassle, just honest and reliable service - A true no quibble warranty

Most of our competitors only offer return to base [RTB] warranties - you have to pay and arrange to get it back to them which can be a hassle. Many others offer warranties that have clauses and if you don't have it serviced yearly by them, at your cost, the warranty will be void.

Other benefits of owning an R-Tech machine include:-

- Free friendly and knowledgeable technical advice via phone and email

- Free machine setup help always available - We want you to get the best from your machine

- Ten year Duty-of-Care on all our machines, giving you piece of mind that spare parts will be available if needed

- Video's to show how to use and setup your R-Tech machine.

- 2 year extended warranties available at a minimal cost.

Don't just take our word for it - see our customer reviews page to see what real customers say about the R-Tech products and our service & support.

-

What is Easy-Setup on the TIG261TFT?

R-Tech Easy mode takes the guesswork out of TIG welding. You normally had to enter all weld settings before beginning to weld on manual welders, we have done this for you.

You simply select the following from easy to understand screen.

Tungsten size

Material thickness

Filler rod material in AC (4043 or 5356)

Material type in DC (Mild or Stainless)

Type of joint - Butt - Lap - Corner - Tee - Edge

Pulse Off/On

Trigger / Pedal mode

The machine will set main amperage power , post flow gas time required and also advise on the recommended gas flow in LPM and ceramic cup size for torch.

Easy-set is ideal for all users - the beginner / occasional / proffesional welder as you can get welding - no need for charts / remembered settings etc as it's all built in for you.

You also have 10A trim +/- of recommended amperage, simply turn knob to decrease / increase amperage.

This is to allow fine tuning to personal preferences like travel speed, weld bead appearance.

-

What is fan on demand and water cooler control on TIG261TFT?

Our TFT machines have advanced features to control the fan and water cooler.

Fan control system

The machine has 3 fan control modes.

ON - Fan on all the time.

MODE1 - Fan by thermal sensor.

The fan will stay off until the inverter temperature monitoring system switches on the fan to cool the machine down and stop when cooling has been sufficient.

This saves on power consumption and also gives a quieter working environment.

MODE2 - Fan on arc ignition.

The machine will start the fan as soon as an arc has been established, it will continue to run for 1 minute after you have finished welding - giving a quieter work enviroment and saving power.

Water cooler control system

The machine has 3 water cooler control modes.

OFF - No power to rear 240V aux power outlet.

ON - Water cooler on all the time

The machine will give 240V continuous output to rear power outlet.

MODE1 - Water cooler on demand

Water cooler is turned on when the arc is started, it will continue to run for 1 minute after you have finished welding to cool torch down and then turn off - giving a quieter work enviroment and saving power. -

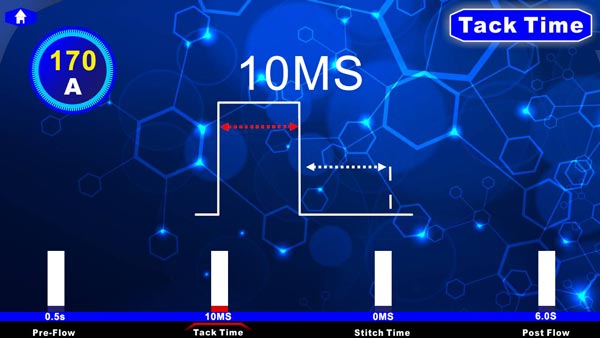

What are the SPOT and TACK function on the TIG261TFT

On the TFT range of machines we added many new advanced functions compared to our previous digital machines. SPOT and TACK weld were two of these additions.

TACK welding allows you to product one single fast tack weld for a selected time when trigger is pressed. You can also set a stitch time which will then set a delay time after first tack and then another tack weld will be started and this will be repeated for as long as trigger is pressed.

Ideal for quick tacking of a job before the main welds are done, each tack will be excatly the same.

Tack time is adjustable between 10ms - 250ms, stitch time 10ms - 250ms

SPOT welding allows you to product one single spot weld for a selected time when trigger is pressed. You can also set a stitch time which will then set a delay time after first spot and then another spot weld will be started and this will be repeated for as long as trigger is pressed.

This is setup in same way as tack weld screen, however spot time is between 0.1s and 10s and the stitch time is 0 - 5s.

-

How does the foot pedal work on TIG261TFT?

This allows you to control the amperage when actually welding which is very beneficial especially when welding aluminium or exotic steels / alloys. It acts like a car throttle controlling the amperage.

You simply unplug the torch switch plug from machine and plug in the foot pedal.

You then set the main control amperage on machine front panel to the maximum you wish the foot pedal to go to on a maximum depression. So if you set the main amperage control to 100amps, when fully depressed the foot pedal will give 100amps. If set to 40 amps, it will go from minimum amps to 40amps allowing fine control of amperage.

Note: Some competitors foot pedals have the maximum amperage knob on the side of the foot pedal, so it can be hard to see what the maximum has been set and also easily knocked as on floor, this is quite an old fashioned way (we changed to machine control of foot pedal max amps over 17 years ago)

Once a weld pool is formed and you are moving along the weld as the heat transfers into the workpiece you may require less amperage as the weld pool width / penetration will get too hot, reducing the welding current with foot pedal will stop this happening.

Over a 300mm long weld, you may need 100amps at the beginning and only 80 amps at the end of weld. Using a foot pedal will give you a uniform weld bead size.

It also allows you to back off the heat from weld if you need to reposition torch / get new filler rod but don't want to stop the weld I.E When doing pipework etc which requires one continuous weld.

Most experienced tig welders prefer to use a foot pedal especially on aluminium and exotic steels / alloys, unless the welding is not being done at a workbench i.e. working on a car etc. -

What is Meant by Duty Cycle on the TIG261TFT?

Duty Cycle refers to how long a machine will operate for before it automatically stops the welding ARC to protect its components from overheating.

A 60% duty cycle at 200 amps would mean that you are able to weld at 200 amps for a maximum of 6 minutes out of 10 before the machine shuts off to cool down.

Higher duty cycles at higher amperage indicate a machine is made from more high quality components, built to withstand the stresses welding places on them.

We believe on a minimum of 35% duty cycle, most of our machines are 60% at maximum amperage. Built to last, ideal for all users - Industrial, D.I.Y, Home workshop.

At R-Tech we believe in building machines to last, with minimum down time to our customers, so we fit the most reliable power modules and IGBT's available coupled with oversized heatsinks. Therefore our machines are able to work harder for longer!

We also quote our duty cycles at machines MAXIMUM amperage unlike some manufacturers who sneakily quote duty cycles NOT at maximum amperage which can be quite misleading! Duty cycle is very important, 20% is not an industrial duty cycle.

I.E Competitors state on thier 200amp machine, 60% duty cycle @140Amps.. So what is the duty cycle @ 200Amps?? -

What are the Benefits of a AC/DC TIG261TFT TIG Welder?

Welding Aluminum - When welding aluminum, you will be using AC mode. We suggest using a foot pedal when TIG welding aluminum as it greatly increases your control over the arc. Easy-Setup you can quickly get welding by just entering thickness and type of joint and the machine sets it all for you, including the correct post flow gas time. Just set and go. In manual mode you have full contol of all parameters.

Welding Stainless Steel - You use DC mode to weld steel and stainless steel on this machine, using Easy-Setup you can quickly get welding by just entering thickness and type of joint and the machine sets it all for you, including the correct post flow gas time. Just set and go. In manual mode you have full contol of all parameters.ARC Control - This can be done via the torch switch or with a foot pedal so you can vary the amperage whilst welding, you have much more control than you would have over a MIG welder.

It also has many torch switching options, 2T, 4T, 4TS (ideal for pipe welding where you need to keep arc established whilst moving workpiece or getting new filler rod)A Great All-Rounder - If you use a lanthanated tungsten, you should find it very straight forward to go from welding mild to stainless steel and then over to aluminum without changing a single consumable. Not only is a TIG welder versatile in the material it can weld, it is extremely versatile in the positions you are able to weld in, be this flat on a bench, vertically and horizontally.

Cleanliness - Welds produced by a TIG welder are extremely clean and should require no cleaning, this makes whatever it is your are working on, ready to go as soon as the weld is completed. As TIG welding produces no sparks, so no spatter.

-

What's the Difference Between Digital TIG261TFT and Analogue Machines?

A Digital TFT machine will do everything an Analogue machine can do in terms of welding capability however they come with extra features to really fine tune your set up and increase productivity. These extra features include the following -

Memory Function -

All TFT digital models come with a 20 job memory function, this allows the user to save multiple pre-sets into the machine. This feature is particularly useful for the welder who finds themselves welding different materials and thicknesses on a continual basis. You simply choose the pre-set you have saved and away you go, no more remembering which position you had a particular dial in.Easy Setup - On TFT AC/DC TIG Welders

We have released the R-Tech EASY SETUP in November 2023 - With over 200 programs built in - getting welding is the easiest it has ever been. No more looking at charts, videos for help or tiral and error, it's all built in for you.

SImply enter tungsten size, material type, material thickness & joint type (corner, butt, lap, tee or edge and the machine will setup correct amperage, post flow gas time and advise cermaic cup size and gas flow required. It is extremely easy to get great welding results quickly - no more guesswork - Ideal for both the beginner welding and experienced looking for quick setup and excellent results.

Colour HD TFT screen -

The most easist navigation system using colour screen, all options on traditional machines had ALL the machine setting on one panel which could be confusing. Now only thr equired parameters needed for weld selected are shown, making it quick and simpler to setup machine.Power Factor Correction -

Gives lower running costs, it is a more energy efficient welding machine, cleans noisy power supplies & is 100% generator friendly increasing the portability of the AC/DC TIG Welder.Lift Start And HF Start -

Lift, which also known as scratch, start is a useful feature when welding close to sensitive electrical components such as ECU's, where HF (high frequency) can potentially damage these components.Lower Range Amperages -

Depending on the model of machine, amperages could start as low as 3amps in the DC process and 5 in AC. There isn't much out there which would require you to be welding at these extremely low amperages however, it works particularly well when pulse welding.Fine Tuning Of Settings -

With all digital machines, you can precisely dial in your amperages, pulse settings, slopes and frequencies. This is all displayed on the digital readout located on the machine. With analogue machines, you only have the dials and indicators to rely on.5 AC Waveforms -

Advanced Square Wave, Soft Square wave, Triangular wave & Sine wave can be selected on the digital machines. By changing the amperage waves, you are changing how the amperages fluctuate and behave during the process -

How Long Will It Take To Get My TIG261TFT?

All orders for R-Tech welding equipment received by 3PM will normally be despatched the same day for next day delivery to the UK mainland, UK Isles may take 48hrs.

Once your order has been placed, will will email you an order confirmation, then a despatch confirmation with tracking number so you can track your order. We mainly use DHL who will often provide a 1 hour delivery time to you.

Simply order on-line or by phone on 01452 733933.

If you require any advice on which welding machine will best suit your requirements, please give us a all and one of our friendly sales/technical team will answer your questions

-

Why should I buy a TIG261TFT from R-Tech?

R-Tech provide you with high quality welding equipment with easy useable features, at exceptional value with un-rivalled direct customer support.

All our machines are robustly built using the latest ultra reliable IGBT inverter power components sourced from Siemens Infineon in Germany & USA.

We give a 5 year collect and return warranty on all our R-Tech machines, a true no quibble warranty. We pay for and arrange collection, repair and return to you. General turn-around is 3-4 days, Can you current supplier offer such fast service?

We also offer a free loan machine service to get you back welding quickly and if arranged before 3pm, this can be delivered next working day for UK mainland.

10 year duty of care on spare parts - We keep a large stock of spares in our Tewkesbury premises.

We build our machines in a modular basis which ensures any future repair bills are kept to a minimum, unlike some manufacturers who build the internals of their machines on just one or two P.C.B's. We ensure ours are designed to have internal components easily replaced ensuring cost effective repairs.

-

What is Included in the Box with the TIG261TFT?

All of our machines include everything to get you welding as quickly as possible, at no additional cost. All you need to do is add your selected filler wire and gas to get going.

All of our TFT AC/DC TIG welders include the following, in the box, at no additional cost.

- 4M WP26 Air Cooled Torch

- Earth Lead

- MMA Lead

- Gas Hose

- Mains Cable

- Argon Regulator

- Owners Manual

- Torch Consumables, Including Tungstens

Additional items such as a Foot Pedal and/or Trolley can be purchased as an optional extra, in the drop down menus.