R-Tech 181 Digital MIG Welder (240v) - Shop Soiled

- Shop Soiled (very minor scuff) - comes with 5 years collect & return warranty

- Crystal clear LCD Display - See all settings on one screen. Get welding quickly!

- EASY SETUP MODES - Professional weld settings built in for 0.6mm and 0.8mm wire - Get great results

- EASY MMA/STICK modes for 6013 and 7018 rods

- Simple to use - Easy navigation - no complicated menus

- Full manual mode with burnback control.

- Spool on gun - ideal for aluminium - easy welding of aluminium with optional spool on gun.

- Metal wire feed assy - Consistent weld bead

- Low splatter weld due to inverter technology

- Infinite control of welding amperage

- High duty cycle - 60% @ 150 amps, 35% @ 180 amps

- Euro style MIG torch

- Heavy duty earth / MMA connections

- 5 year collect and return UK warranty

- Want to try before you buy? Book a demonstration at our Tewkesbury HQ - Available 5 days per week 9am-12pm and 2pm-4pm.

| Amperage Range MIG | 30A - 180A | ||

| Input voltage/amps | 240v 16A | ||

| Duty cycle | 35% @ 180A | ||

| Amperage range MMA | 20 - 160A | ||

| Wire reel size | 5KG | ||

| Wire diameter | 0.6mm , 0.8mm | ||

| Roller size fitted | 0.6mm , 0.8mm | ||

| Net weight | 15KG | ||

| Dimensions | 320 x 210 x 420 mm (H x W x D) | ||

| Euro style torch | Yes - Easy fitment of torch | ||

| Gasless wire | Yes - Easy reversal of polarity for gasless wire | ||

| Max Thickness Steel | 6MM Single Pass | ||

| Max Thickness Steel | 15MM Multiple Passes | ||

5 year collect and return UK warranty - What is this?in the unlikely event of machine failure, R-Tech will pay to collect, repair and return the MIG welder to you quickly- No quibble warranty

Generator Friendly - Generator must be minimum of 6KVA 240V and fitted with AVR (auto voltage regulation)

Package Includes: R-Tech MIG181 MIG Welder *Shop Soiled*, 3M MB15 Air Cooled MIG Torch, Earth Lead, Gas Hose, Mains Cable, Gas Regulator, Owners Manual

The R-Tech MIG181 *Shop Soiled* carries the following warranty:-

- MIG181 - 5 Year Warranty

- Regulator - 1 Year Warranty

- R-Tech MIG Torches - 3 Month Warranty

- Earth Lead - 3 Month Warranty

- Optional Spool Gun - 1 Year Warranty

R-Tech machines are designed to be robust, easy to use and highly reliable but in the unlikely event that your welder or plasma cutter requires attention, R-Tech promise to:-

- Arrange collection via next working day UK courier [48hr offshore]

- Quickly repair the machine at our Technical and R&D centre in Gloucester

- Deliver back via next working day UK courier [48hr offshore]

- All costs covered by R-Tech - Yes, Collection, repair and delivery!

No questions, no hassle, just honest and reliable service - A true no quibble warranty

Most of our competitors only offer return to base [RTB] warranties - you have to pay and arrange to get it back to them which can be a hassle. Many others offer warranties that have clauses and if you don't have it serviced yearly by them, at your cost, the warranty will be void.

Other benefits of owning an R-Tech machine include:-

- Free friendly and knowledgeable technical advice via phone and email

- Free machine setup help always available - We want you to get the best from your machine

- Ten year Duty-of-Care on all our machines, giving you piece of mind that spare parts will be available if needed

- Video's to show how to use and setup your R-Tech machine.

- 2 year extended warranties available at a minimal cost.

Don't just take our word for it - see our customer reviews page to see what real customers say about the R-Tech products and our service & support.

-

What is Easy-Set technology on the MIG181?

Easy-Set technology takes the guess work our of setting up machine for your desired weld. You simply use two buttons to select wire size being used and material thickness to weld.

The machine then sets the wire speed and welding power accordingly, you then just press the trigger and start welding - it is that simple!

Easy-set is ideal for all users - the beginner / occasional / proffesional welder as you can get welding by the press of 2 buttons - no need for charts / remembered settings etc as it's all built in for you.

You also have a trim for wire speed and welding power, so you can trim it +/- to suit your personal preference of travel speed / weld bead thickness.

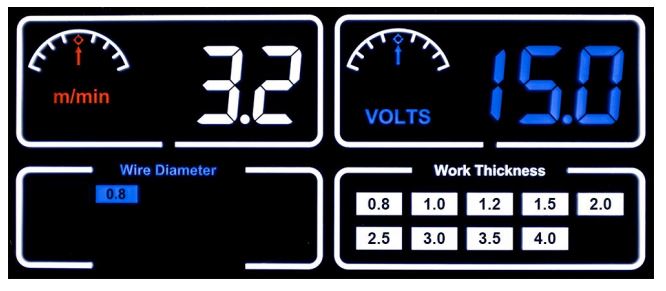

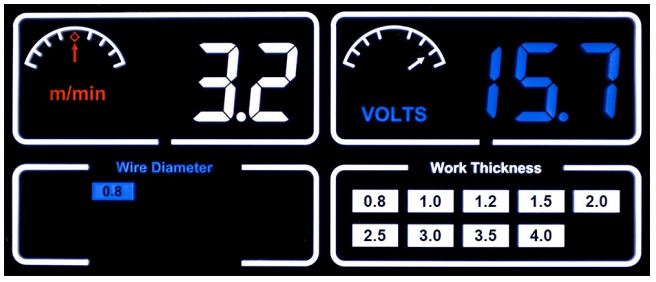

In image below, using 0.8mm wire, you have selections for 0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0mm - Just select thickness and get welding.

If you want to fine tune the weld characteristics to suit your personal preference.

You can trim the wire speed by 1 m/min by turning wire speed knob.

You can trim the welding voltage by 1V by turning welding voltage knob. -

What settings are there in manual mode on MIG181?

In MIG Manual mode, you have full control of machine settings including.

Wire feed speed 1.5 - 12 m/min

Welding voltage 13V - 23V

2T/4T trigger options

Burnback control 0s - 2s

Spool on gun operation off/on

2T - Press trigger to start weld, release to finish weld.

4T - Press and release trigger to start weld, To finish weld press and release trigger.

This is commonly know as trigger latching.

Burnback is how long the welding power will continue after wire feed has stopped, this stops the wire from sticking to workpiece when weld finished -

What is Meant by Duty Cycle on the MIG181?

Duty Cycle refers to how long a machine will operate for before it automatically stops the welding ARC to protect its components from overheating.

A 35% duty cycle at 180 amps would mean that you are able to weld at 180 amps for a maximum of 3.5 minutes out of 10 before the machine shuts off to cool down.

Higher duty cycles at higher amperage indicate a machine is made from more high quality components, built to withstand the stresses welding places on them.

We believe on a minimum of 35% duty cycle, most of our machines are 35%-60% at maximum amperage. Built to last, ideal for all users - Industrial, D.I.Y, Home workshop.

At R-Tech we believe in building machines to last, with minimum down time to our customers, so we fit the most reliable power modules and IGBT's available coupled with oversized heatsinks. Therefore our machines are able to work harder for longer!

We also quote our duty cycles at machines MAXIMUM amperage unlike some manufacturers who sneakily quote duty cycles NOT at maximum amperage which can be quite misleading! Duty cycle is very important, 20% is not an industrial duty cycle.

I.E Competitors state on thier 200amp machine, 60% duty cycle @140Amps.. So what is the duty cycle @ 200Amps?? -

Can I Stick/MMA Weld With An R-Tech MIG 181?

Yes you can, the MIG 181 is fitted with stick welding functionality and will comfortably burn rods up to 4.0mm smoothly. This makes the MIG 181 suitable for agricutural welding jobs such as digger buckets, railings and gates posts.

With the Easy-Set function, you simply select rod size being used I.E 2.4 / 3.2mm and thickness of material to be welded, the machine sets required power for you, then just start welding, it is that easy! -

Can I Run The R-Tech MIG 181 on a Standard 13amp Plug?

Yes you can.

Thanks to its effiecient inverter technology, the MIG 181 will generate up to 140-160 amps smoothly on a standard 13A household plug.

This makes the machine perfect for welding up to 4.5mm and very portable as you can use anywhere with a 13A socket.

For full continued use at 180 amps, you will require a 16A supply, which is quite easily fitted to most workshops. -

Why is a Euro MIG torch on MIG181 superior to a fixed torch?

We fit Euro style torches on all of our MIG welder range.

These have many benefits over machines with a fixed torch as found on the basic / DIY machines.They give consistent wire feed speed giving a more uniform weld.

Easy fitment if torch becomes damaged - for fixed torches you will have to dis-assemble part of the machine.

Easier to change liners if they become worn

Better feel in the hand, Euro torches are generally better quality.

You can easily select preferred style of euro torch and fit quickly and easily. -

Which Are The Best Wire Diameters To Use In The MIG 181?

You can use both 0.6mm and 0.8mm diameters in the R-Tech MIG 181. We get excellent results when we use the following -

For anything 2mm and below, such as car body work, we would recommend 0.6mm wire thickness. This is because the wire requires a much lower amperage to achieve briliiant penetration and prevents burning holes in the work piece.

For anything 2-3mm and above, such as chassis work, steel fabrication we would recommend 0.8mm wire thickness. This wire thickness is a fantastic all rounder as it suites many of the users requirements.

Our machines are fitted with a double grooved roller to suite both 0.8mm and 0.6mm wire. Simply unscrew the retaining screw from roller, turn the roller around to match the wire diameter and re-install the retaining screw.

-

Which Gas Do I Need To MIG Weld on the MIG181?

We recommend using a gas that contains 95% Argon and 5% Carbon Dioxide for any welding less than 6mm.

Gas MIG welding will always give you the best results, the MIG181 also supports gasless MIG wire, this is ideal if welding outside or where gas is unavailable.

Gas bottles can be purchased from many outlets and you have option of buying the bottle and gas, when bottle is empty - return bottle for a fully filled one, this is generally know as 'rent free bottles'

For high / industrial use, you can purchase via a rental agreement normally paid by direct debit - more cost effective for high volume users.